Clay Mineral

Blasting Materials distributed by GritSablare are characterized by outstanding quality. This quality is reflected in an above-average service life, a very high productivity and value retention.

Sodium Bentonite for Foundry, Drills

Bentonite for Food Industry (99,9% Purity)

- High quality Sodium Bentonite obtained from premium bentonite mineral clays, with rich content of montmorillonite, an ideal additive for foundry industry, drilling, construction;

- Uses: binder in casting molding mixtures • drilling fluids preparation to lubricate and cool the cutting tools, to remove cuttings, and to help prevent blowouts • oil refinery • groundwater barrier • slurry walls in modern construction • electrical grounding sealing • in pottery to make the clay mixture more plastic • for decolorizing various mineral, vegetable, and animal oils • for clarifying wine, liquor, cider, beer, mead, and vinegar.

PREMIUM Bentonite

99,9% Purity

- Origin of Argentina

- Extra-fine size:

Sieve Analysis 200 Mesh (0,053mm): ~0.5% - Bags of 20 Kg (Moisture Proof Paper Bags)

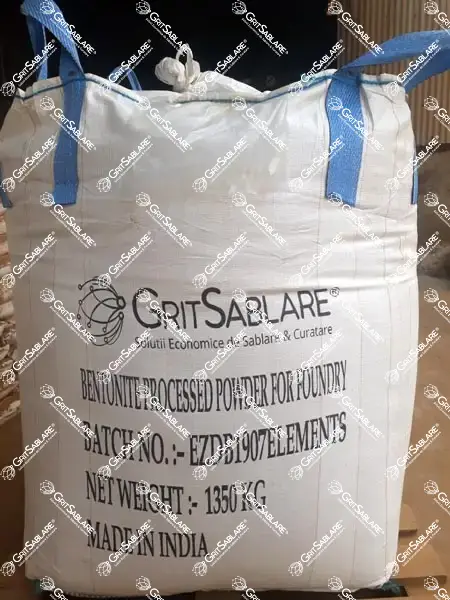

DRB Bentonite

- Origin of India

- Bags of 20 Kg (Moisture Proof Paper Bags)

- Big Bags of 1350 Kg

SUPER-BOND Bentonite

- Origin of India

- Super-fine size:

Sieve Analysis 200 Mesh (0,053mm): ~20% - Bags of 20 Kg (Moisture Proof Paper Bags)

- Big Bags of 1350 Kg

- The material must be stored in a dry place.

DRB Bentonite: Drilling & Civil Engineering

DRB Bentonite is a premium range of Sodium Bentonite products which contains rheological and thixotropic properties that offer distinct advantages for Trenchless Engineering (Horizontal Directional Drilling, Micro Tunneling, Pipe Ramming, Pipe Jacking and Horizontal Auger Boring), Piling, Water Well Drilling, Diaphragm Wall, Grouting and for many other Civil Engineering and Drilling applications.

Features of our products that will make your project run smoothly and efficiently

- Cooling and lubricating drilling head during drilling process.

- Suspending and carry away the drill cuttings from borehole.

- Stabilizing borehole.

- Reducing frac-outs and ground heaving.

- Good carrying capacity (gel strength).

- Supports excavation by maintaining hydraulic pressure on walls.

DRB Bentonite Types

DRB Bentonite HDD

DRB Bentonite HDD is a high montmorillonite Sodium Bentonite that works best as lubricating and supporting agent in Trenchless Engineering, Civil Engineering and many other Drilling applications for non-reactive soil type such as clay. It helps to shingle off the wall of the bore hole and forms a filter cake that cuts off the flow of fluid into the surrounding soil. This gives good soil and cutting caring capacity.

DRB Bentonite HDD+

DRB Bentonite HDD+ is high yield polymer treated Sodium Bentonite which have a yield of approx 150 bbl and can be used for all type of soil including reactive clay such as sand, rock or gravel and works well with all Trenchless Engineering, Civil Engineering and many other Drilling applications. DRB Bentonite HDD+ provides additional secondary filtration control and high viscosity. This will also helps to clean the drill bit and help with the cutting removal.

DRB Bentonite HDD PRO

Extra high yield Sodium Bentonite has a higher performance formula that makes it a very effective viscosifier and has a yield of approx 220 bbl. This premium grade Sodium Bentonite is designed for use in Trenchless Engineering, Civil Engineering and many other Drilling applications. It is an efficient viscosifier that performs well in all soil type, successfully reduces application rates, and mixes quickly and easily.

DRB Bentonite Technical Details

| Product | Yield/MT | Dosage | Applications |

|---|---|---|---|

| DRB Bentonite HDD | 110 bbl Minimum | 55 to 60 Kg per in 1000 litre fresh water | Trenchless Engineering (Horizontal Directional Drilling, Micro Tunneling, Pipe Ramming, Pipe Jacking and Horizontal Auger Boring ), Piling, Water Well Drilling, Diaphragm Wall, Grouting and other Civil Engineering and Drilling applications |

| DRB Bentonite HDD+ | 150 bbl Minimum | 40 to 45 Kg per in 1000 litre fresh water | Trenchless Engineering (Horizontal Directional Drilling, Micro Tunneling, Pipe Ramming , Pipe Jacking and Horizontal Auger Boring ), Piling, Water Well Drilling, Diaphragm Wall, Grouting and other Civil Engineering and Drilling applications |

| DRB Bentonite HDD PRO | 220 bbl Minimum | 25 to 28 Kg per in 1000 litre fresh water | Trenchless Engineering (Horizontal Directional Drilling, Micro Tunneling, Pipe Ramming , Pipe Jacking and Horizontal Auger Boring ), Piling, Water Well Drilling, Diaphragm Wall, Grouting and other Civil Engineering and Drilling applications |

| DRB Bentonite API 13 A Section 9 | 90 bbl Minimum | 64 Kg per in 1000 litre fresh water | Oil/Gas Well Drilling |

| DRB Bentonite API 13 A Section 11 (OCMA) | 90 bbl Minimum | 64 Kg per in 1000 litre fresh water | Oil/Gas Well Drilling |

| DRB Bentonite Chips/Granules | NA | NA | Sealing and grouting well casings, plugging abandoned wells, and water-proofing earthen structures |

DRB Bentonite Application

Drilling fluids

Sodium bentonite is a major component for the drilling fluids in oil and gas industry.

- It is used in drilling for the preparation and conditioning of drilling fluids. Bentonite is the most used material to increase the viscosity of the drilling fluid.

- Bentonite is a thixotropic material, which allows the water-bentonite mixture to take on the characteristics of a gel when in resting state, and to become liquid again when the mixture is stirred, the gel being reversible.

- The water-bentonite mixture in gel state allow the isolation of the drilling fluid in the well, ensuring the vertical stability of the trench, preventing it from collapsing.

When the hole collapse on top of drill string it will become difficult for string to rotate or move and will stuck into collapsed soil.

Frac-out is a condition where drilling fluid penetrates in to surrounding soil and creates serious environmental problems.

Removal of cutting is essential for the performance of the drilling process. If soil debris build up on lower side of hole then this will cause blockage which stuck the pipe or drilling tools to excavation path.

SUPER-BOND Bentonite: Foundry & Grounding

- The SUPER-BOND Bentonite offered by GritSablare is extracted from carefully selected clays with high montmorillonite content in India, with superior mechanical and compressive strength.

- Highest green compression strength

- High swelling/wet tensile strength

- Develops sharp, strong mould in foundry industry

- Good bond development and easy mulling

- High swelling capacity for drill fluids

- Wide moisture tolerance

SUPER-BOND Bentonite Application

Binder in moulding sands in foundry industry

Sodium bentonite is one of the most commonly used foundry-sand binder in iron and steel foundries.

- High Swelling and Wet Tensile strength helps for exceptional resistance to expansion and permeability of moulding sands to avoid casting defects like porosity, blow holes and open holes, scabbing, rough surface.

- Unlike other clays, bentonite is up to three times more efficient, when used as a foundry-sand bond in iron and steel foundries, which leads to a reduction of the additive in the furnace in order to obtain the same tensile strength and permeability of the mould.

- Our Bentonite has characteristics of smooth, quick & uniform dispersal during dry mixing of sand mix which reduces binder addition & Sand Mixing/ Mulling Time.

Pool Foundation & Grounding

Sodium Bentonite has superior swelling capacity compared to other bentonite products on the market – our product adsorbs up to nearly 16 times its weight in water, and after complete saturation, it occupies a volume between 12 to 15 times higher than its original volume – being an ideal product for soil sealing as it is swelling within the interstices of the soil with which is mixed, creating a barrier of very low permeability. Swelling ability is enhanced due the small particle size of the product, allowing bentonite to plug even the smallest of soil voids. Therefore, a soil bentonite mixture creates a highly durable barrier for long periods of time.

Description

- High quality sodium bentonite: mineral clay resulted from the alteration of volcanic ashes, with rich montmorillonite content. Bentonite is a soft and durable clay, with a greasy aspect. The colour varies depending on the natural pigments it contains, from white to gray, with pink and cream variations;

- The outstanding properties of the bentonite recommend this product to be an extremely useful material in many industries:

- It increase the tensile strength and permeability of the molding sands, in foundry industry;

- Ideal for the preparation and conditioning of drilling fluids (due to its thixotropic features and high suspension stability);

- Groundwater barrier for drilling wells and water sealing for underground constructions;

- Oil and oil derivates refinery (due to its high adsorption and absorption capacity).

Bentonite Application

Bentonite is being currently authorized as animal feed additives for Mycotoxins binder and for anticaking agent. Our selected premium Sodium Bentonite has a high Montmorillonite content and also a very high adsorbent capacity due to the presence of negative charges on the surface. Owing to this high adsorbent property, it eliminate Mycotoxins such as aflatoxin B1 and other substances which is very harmful for various animal species.

Besides this it is also beneficial for improvement of cattle, adsorption of organic contamination and improvement in the strength property of feed pellets. The physical and chemical structure of Bentonite facilitates the superficial absorption of proteins and amino acids.

- Protein Binder: Bentonite protect the proteins and amino acids from microbial fermentation occurring in the rumen. It also can improve feed efficiency, milk production, wool growth and egg production.

- Applicable for all Species Feed Additive: Bentonite is an effective feed additive for poultry, pigs, dairy cattle, horses, sheep and deer.

- Environment Friendly: Bentonite is ubiquitous soil components, and their use in animal production is not expected to adversely affect the environment.

- Dioxin Free: Dioxins are highly toxic and can cause cancer, reproductive and developmental problems, damage to the immune system once entered into animal body. We are taking all precautions while making animal feed additive grade to avoid Dioxin.

Other Uses:

Physical and Chemical Properties

| Physical Properties: | PREMIUM Bentonite Argentina | SUPER-BOND Bentonite India |

|---|---|---|

| Green Compression Strength: | 13,0 min (N/cm2) | 1100 la 1800 gram/cm2 |

| Wet Tensile Strength: | 0,31 min (N/cm2) | > 0.35 la < 0.50 N/cm2 |

| Methylene Blue Adsorption original (mL /0,5g): | 56 min. | - |

| Methylene Blue Adsorption, 550 o.C (mL /0,5g): | 42 min. | - |

| Methylen Blue Value (MBV): | - | 410 Min |

| Thermal Stability (%): | 75 min. | - |

| Swelling: | 40 min. (mL/2,0g) | 33 - 36 (2 gm / 100 ml) |

| Moisture (%): | 08 - 12 | 12% Max |

| Retention #200 (%): | 08 max | - |

| Compactability (%): | 47 +/- 1 | - |

| pH: | 6,6 - 7,8 | 8 - 10,5 |

| Gelling Time at 10% (min): | - | 0 - 60 seconds |

| Gel Formation Index: | - | 90 - 100 |

| Loss on Ignition (LOI): | - | < 10 % |

| Chemical Composition (%): | PREMIUM Bentonite Argentina | SUPER-BOND Bentonite India |

|---|---|---|

| SiO2: | 57,8 | 45 - 55 |

| Al2O3: | 18 | 14 - 19 |

| Fe2O3: | 4,41 | 11 - 19 |

| TiO2: | 0,22 | 0,8 - 4 |

| CaO: | 0,99 | 0,7 - 2,4 |

| MgO: | 2,78 | 1,9 - 3,6 |

| Na2O: | 2,91 | 1,6 - 3,2 |

| K2O: | 0,39 | 0,12 - 0,3 |

| MnO: | <0,10 | - |

| P.F.: | 11,8 | - |

Testimonials

A beautiful collaboration, quality, promptitude and honesty carried us on a beautiful road...

Răzvan Harabagiu, Shareholder | Executive Manager, Alpaccess, Romania

A trustworthy brand, a professional team, a flawless service! We are happy to have them as our supplier for blasting agents and equipment.

Iulian Duna, Project Manager, Industrial Cruman, Ploiești - Romania

GritSablare, a reliable and fast partner, always involved to learn and find solutions that fits customers' needs.

Daniel Morari, COSMA Glass - water jet cutting

GritSablare, the largest blasting warehouse we are aware of... a flexible payment schedule for blasting equipment, moreover, a very good choice!

Ionel Zelca, Owner, Industrial Painting SRL - blasting and electrostatic painting

We provide first-class quality products, build long term relationships and develop strong connections with our clients