Air – the indispensable element of the life on Earth, since the moment we are born, and until we leave this world… so important, and yet, you can’t even see it, and if you think about, we are not aware of the time when we’re breathing: is not like trying to inhale and exhale at regular times, but everything happens by the means of a remarkably complex instinctual mechanism. Air covers the Earth creating the atmosphere which protects us of the negative impact of the UV radiation; air currents are the winds which are captured by the wind turbines to generate green energy; air is the one that’s filling your chest when you’re breathing, allowing you to be alive, able to concentrate, and able to meditate through breathing techniques; air, when compressed, becomes a resource used in industry and construction for developing human societies – all of these, being the facets of the same and unequalled phenomenon.

What is compressed air?

Compressed air is, in fact, air taken from the atmosphere that is kept at a higher pressure than the atmospheric one, with the help of a compressor. It is considered to be the fourth source of energy in the industry after: electricity, natural gas and water, with many applications in different areas: industry (pneumatic tools, HVAC systems, painting installations), mechanical propulsion (compressed air vehicles), energy storage, braking systems design, breathing air for respirators used in toxic environments and underwater, refrigeration systems (vortex tubes), injection moulding (for plastics and rubber), surface preparation systems and blasting of metallic and non-metallic parts.

There are multiple types of air compressors on the market that can produce compressed air, with different degrees of purity, considering the needs of every type of applications: (1) oil-free compressors which produce air at the highest purity level, for applications where no contamination is allowed: • medical procedures, • food and beverages, • air bubble curtains, which are placed at the bottom of the sea during off-shore wind turbine construction, in order to reduce the noise level in the sea up to 95%, considering that the life of marine animals is endangered in case of high levels of noise, which also creates the inability of these animals to guide themselves into the waters, • supplied-air respirators used in case of toxic environments (like blasting and painting), and also (2) oil-based air compressors, where the purity of the compressed air is less significant, with multiple technical applications in different industries.

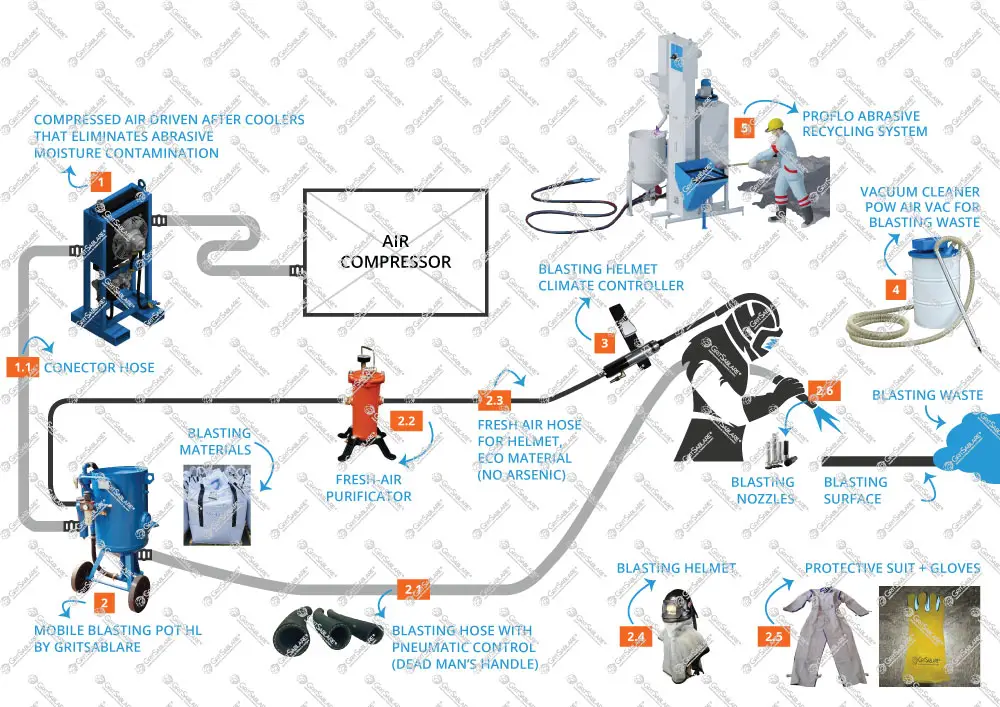

Large amounts of compressed air are consumed in the field of blasting, but the volumes differ significantly depending on the extent of the blasting applications required. When choosing an air compressor for blasting applications, one should consider the number of air consumers, and the type of the surface to be prepared. The following diagram presents a typical example on how the air consumers are connected to the air compressor in a blasting application.

When choosing an air compressor, one should consider two main metrics: CFM and PSI:

- CFM (Cubic Feet per Minute) represents the volume of air a compressor can supply in one minute. An air compressor that supplies between 10 and 20 CFM is ideal for small blasting applications, while an air compressor that supplies between 18 and 35 CFM of compressed air is ideal for larger blasting applications, where more powered is required. Industrial blasting applications require between 50 and 100 CFM, or even more.

- PSI (Pounds per Square Inch) represents the air pressure of an air compressor. When choosing the right PSI for blasting, one should consider the duration of blasting applications and the number of consumers that are simultaneously connected to the compressor. A high PSI number means a more efficient blasting in a shorter period of time, but higher operative costs. Still, it is accepted that an air compressor of a minimum 100 PSI is an ideal choice for blasting applications. If the pressure is reduced by half, the duration of blasting operation will increase four times.

GritSablare is a Romanian leader in blasting field and provides a complete solution for any type of blasting application: ecological and non-toxic blasting media (including water-jet cutting abrasives), professional blasting equipment for small and also large blasting applications, and also air compressors for blasting applications, of three types:

- Electrical air compressors used mainly for indoor blasting applications, for blasting rooms, blasting cabinets and blast wheels.

- PTO (power-take-off) driven air compressors which can be attached either in the front or in the rear of the tractor, used mainly in outdoor blasting application on any type of terrain.

- Diesel driven air compressors for outdoor blasting applications, that offer high mobility on working and construction sites with no infrastructure, and no access to electric power.

We are actively involved in finding new competitive solutions with our partners, to provide the latest technologies in air compressors for our clients, at an optimal price-quality ratio, but also with the guarantee of a fast response in case of equipment failure, for units purchased from our company. Since our establishment, we pursued the leadership position in blasting and cleaning solutions, so our clients could find the best solutions and technical expertise for every blasting requirement. We have so many ideas, so much will, that is impossible not to succeed!