Tumbling Media for

Vibratory Tumbler and Vibratory Finishing Machine

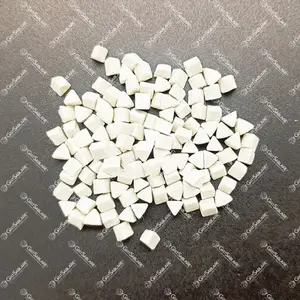

Resin and Plastic Tumbling Media

Description:

- Application: Light material, for zinc alloy, aluminum alloy, lead alloy and copper surface deburring, without scratching the workpiece. Easily foaming during water treatment.

- Content: Resin abrasive media, also known as plastic abrasive media, which is made of high-quality unsaturated resin and a certain number of micro-powder cured in different specifications.

- Uses: Used to remove burrs, flash, oxide, rust, and creases on the surface of metal and non-metal workpiece.

Other shapes:

| Physical Properties | |

|---|---|

| Shape: | Tetrahedron, Cone, Pyramid |

| Colour: | Green, red, yellow, black etc. |

| Error range: | ±1mm |

| Resin content: | ≥45% |

| Density: | 1.80g/cm3 |

| Mesh: | 400, 800, 1200 |

| Size: | 10mm x 10mm - 30mm x 30mm |

| Attrition rate: | ≤2.5% (Centrifuge self-grinding test data for 1 hour) |

| Packing: | 25kg / woven bag; 40 bags / pallet |

| Remarks: | Customized media size & shape available |

| Chemical composition | |

|---|---|

| Resin | 45 |

| SiO2 | 40 |

| CaO | 3.2 |

| Na2O | 2.5 |

| Other | 9.3 |

Corundum Ceramic Deburring Media

Description:

- Features: Extremely strong cutting force, low density (high consumption).

- Content: Corundum ceramic abrasive media, it's made of high-quality corundum sand (non-recycled) and ceramic binder, cutting to different shapes, finalized by high temperature calcination. Main components are SiO2 and Al2O3.

- Uses: Mainly for metal workpiece deburring, deflash, descaling etc.

Other shapes:

| Physical Properties | |

|---|---|

| Shape: |

• ACT (Angle Cut Triangle) • ACTS (Angle Cut Tri-Star) • ACE (Angle Cut Ellipse) • Irregular • Con • SCT (Side Cut Triangle) • SCTS (Side Cut Tri-Star) • Sphere |

| Colour: | Dark blue (grey) |

| Density: | 2.2g/cm3 - 2.5g/cm3 |

| Moh's hardness: | ≥L7 |

| Mesh: | 80, 120, 240 |

| Size: | • Sphere: 1mm - 20mm, • Other shapes: 3mm x 3mm - 30mm x 30mm |

| Attrition rate: | ≤1.5% (Centrifuge self-grinding test data for 1 hour) |

| Packing: | 25kg / woven bag; 40 bags / pallet |

| Remarks: | Customized media size & shape available |

| Chemical composition | |

|---|---|

| Al2O3 | 13.28 |

| SiO2 | 49.6 |

| K2O | 6.84 |

| CaO | 21.08 |

| TiO2 | 3.25 |

| Fe2O3 | 1.68 |

| Na2O | 1.8 |

| MgO | 2.47 |

High Density Chrome Corundum Deburring Media

Description:

- Features: Rough polishing, moderate polishing and elaborate polishing all in one process. Not applicable to soft workpiece.

- Content: High density ceramic abrasive media, chrome corundum as main subject composed of metal binder, united into a new combination of abrasive media, which makes the product have greater strength and density.

- Uses: Used for metal parts deburring and elaborate polishing, has better effectiveness for high hardness material workpiece.

Other shapes:

| Physical Properties | |

|---|---|

| Shape: |

• ACT (Angle Cut Triangle) • ACC (Angle Cut Cilinder) • Irregular • SCT (Side Cut Triangle) • SCC (Side Cut Cilinder) • Sphere |

| Colour: | Negru |

| Density: | 3.6g/cm3 |

| Moh's hardness: | ≥L8 |

| Mesh: | 2000 |

| Size: |

• Sphere: 1mm - 6mm, • Irregular: 60 Mesh - 6 Mesh, • Other shapes: 3mm x 3mm - 30mm x 30mm |

| Attrition rate: | 0.8% |

| Packing: | 25kg / woven bag; 40 bags / pallet |

| Remarks: | Customized media size & shape available |

High Alumina Ceramic Polishing Media

Description:

- Features:Repair scratches on parts surface during bright polishing. High density but low cutting force.

- Content: High alumina ceramic abrasive media, α-alumina as the main crystal phase, with ceramic binder, cutting to different shape, finalized by high temperature calcination. Main component is Al2O3.

- Uses: Mainly used for elaborate polishing of the surface of various metal and non-metal workpiece which after rough polishing and moderate polishing, increase the workpiece surface smoothness and brightness.

Other shapes:

| Physical Properties | |

|---|---|

| Shape: |

• ACC (Angle Cut Cilinder) • ACT (Angle Cut Triangle) • ACTS (Angle Cut Tri-Star) • Irregular • SCC (Side Cut Cilinder) • SCT (Side Cut Triangle) • Sphere |

| Colour: | White, green, red, yellow, etc |

| Density: | 2.9g/cm3 |

| Moh's hardness: | ≥L8 |

| Mesh: | 800, 1500 |

| Size: | • Sphere: 1mm - 20mm, • Other shapes: 3mm x 3mm - 30mm x 30mm |

| Attrition rate: | 0.2% |

| Packing: | 25kg / woven bag; 40 bags / pallet |

| Remarks: | Customized media size & shape available |

Yttrium Stabilized Zirconia Tumbling Media

Description:

- Features: The yttrium stabilized TZP zirconia ceramic beads have a specific gravity of 1.6 times that of ordinary zirconia beads, and have higher grinding efficiency under the same conditions. Good fluidity, good roundness and smooth surface, and the wear of the equipment is lower than other grinding media.

- Content: Zirconia ceramic bead has high strength, high toughness, good wear resistance, high temperature resistance, high corrosion resistance, high rigidity, non-magnetic permeability and electrical insulation under normal temperature condition. Main component is ZrO2.

- Uses: It has been widely used in the ultra-fine grinding and dispersion of materials, such as metal material, non-metallic minerals(gold ore), oil paint, inks, dyes, titanium dioxide, pesticides, magnetic material and other industries.

| Content ZrO2 | 30% | 65% | 85% | 95% |

|---|---|---|---|---|

| Density: | 3.4 g/cm3 | 4.1 g/cm3 | 5.3 g/cm3 | 6.1 g/cm3 |

| Refractory temperature | 1500°C | 1700°C | 1750°C | 1800°C |

| Strength (2mm) | 700N | 1100N | 2000N | 150KGF |

| Moh's hardness | ≥L8 | ≥L8 | ≥L9 | ≥L9 |

| Physical Properties | |

|---|---|

| Shape: |

• SCC (Side Cut Cilinder) • Sphere |

| Colour: | Crystal white |

| Density: | 3.4g/cm3 - 6.1g/cm3 |

| Moh's hardness: | ≥L8 - L9 |

| Mesh: | - |

| Size: | 0.4 mm x 30 mm |

| Attrition rate: | 0.1% |

| Packing: | 25kg / plastic drum |

| Remarks: | Customized media size & shape available |

Vibratory Tumbler and Vibratory Finishing Machines

Testimonials

A beautiful collaboration, quality, promptitude and honesty carried us on a beautiful road...

Răzvan Harabagiu, Shareholder | Executive Manager, Alpaccess, Romania

A trustworthy brand, a professional team, a flawless service! We are happy to have them as our supplier for blasting agents and equipment.

Iulian Duna, Project Manager, Industrial Cruman, Ploiești - Romania

GritSablare, a reliable and fast partner, always involved to learn and find solutions that fits customers' needs.

Daniel Morari, COSMA Glass - water jet cutting

GritSablare, the largest blasting warehouse we are aware of... a flexible payment schedule for blasting equipment, moreover, a very good choice!

Ionel Zelca, Owner, Industrial Painting SRL - blasting and electrostatic painting

We provide first-class quality products, build long term relationships and develop strong connections with our clients