FREE: we provide blasting waste recovery services for materials purchased from us. Offer subject to certain terms and conditions.

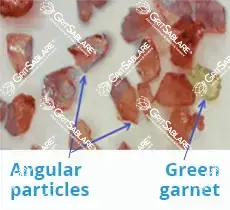

Angular Shape

Blasting Materials distributed by GritSablare are characterized by outstanding quality. This quality is reflected in an above-average service life, a very high productivity and value retention.

Red Garnet for Water Jet Cutting

- Ideal for water jet cutting thanks to its unique series of features such are: hardness, density, friability and particle shape;

- The material contains green granat particles of superior hardness, which ensure an enhanced cutting force;

- Superior Toughness: Mohs Hardness 7.0 - 8.0;

- Ecological Product and Non-Toxic Material (Low Free Silica Content <0.1%).

UE Regulations

- 80 Mesh

- 120 Mesh

- Bags of 25 Kg

[All types] - Big Bags of 1 Tonne

[All types]

- The material must be stored in a dry place.

We offer comprehensive blasting waste recovery services for neutralization. For further details, please contact us.

Red Garnet Description

SUPERIOR HARDNESS

High-quality iron-aluminium garnet, garnet in the effective content of Al2O3 and Fe2O3; in addition to red garnet is green garnet, the naked eye looks like black spots, can be seen under the magnifying glass is green garnet. So the garnet hardness is higher.

BETTER CUTTING EFFECT

From the rock mine, preserved garnet crystal structure, the angular shape is the sharp 12-sided or four corners, 38-dimensional structure after crushed, with the rich, sharp edges and edges and toughness, cutting better.

HIGHER RECYCLING RATE

Because deep underground, not subject to natural erosion, broken grain is angular sharp, through 4 times broken, high hardness and toughness, used as blasting and cutting abrasive, can achieve multiple re-use.

- The best abrasive for water jet cutting machines is the red garnet, thanks to a unique series of features such as: hardness, density, friability and particle shape, that maximize the cutting properties of water jet machines:

- Hardness. Water jet cutting needs an optimal balance between the cutting force and the wear of the cutting machine parts. A soft abrasive prolongs the life of the nozzles, but slows down the cutting. An abrasive too tough increases the cutting speed, but erodes the nozzles too quickly, leading to dead operating times and increases in the costs of repairing machine parts. The hardness of red garnet is about 8 on Mohs scale, which effectively balances the need to cut quickly, but also provides a reasonable operating lifetime for the equipment;

- Density. The cutting force of water jet machine is a function of two factors: the weight of the abrasive multiplied by the velocity. The ideal abrasive has the greatest weight that water can accelerate to maximum velocity, offering ultimate cutting speed. An abrasive that is too light will not cut the material and a material that is too heavy will not accelerate to the maximum velocity, slowing down the cutting speed. Red garnet is almost four times heavier than the water, a value that falls in the optimal range for both cutting and acceleration;

- Friability. Red garnet with its semi-friable nature that makes it fracture in angular particles with sharp edges when passing through the nozzle, provides superior cutting speed than any other abrasive material;

- Particle shape. It has been found that the angular shape with multiple sharp edges like the shape of red garnet, is the most suitable for high cutting speeds.

| Physical and Chemical Properties | |

|---|---|

| Physical Form: | Solid |

| Color: | Reddish brown to pink and green |

| Odor: | Odorless |

| Bulk Density: | (approx.) 2.4 g/cm3 |

| Water Solubility: | Insoluble |

| Flammability (solid, gas): | Non-flammable |

| Explosive Properties: | Non-explosive |

| Chemical Composition | |

|---|---|

| Fe2O3 | 38,1% |

| SiO2 (non-crystalline): | 35,2% |

| Al2O3: | 18,9% |

| MgO: | 2,5% |

| P2O5: | 0,06% |

| Na2O: | 0,03% |

| ZrO2: | 0,03% |

| K2O: | 0,02% |

| TiO2: | 2% |

UE Regulations

Regulation (EC) No 1272/2008 of the European Parliament and of the Council of 16 December 2008 on classification, labelling and packaging of substances and mixtures, amending and repealing Directives 67/548/EEC and 1999/45/EC, and amending Regulation (EC) No 1907/2006;

Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH).

Red Garnet Application

Red Garnet User Safety

Red Garnet is a safe, ecologic and stable material. It does not need special attention while handled. Wearing personal protection equipment is necessary, as well as avoiding eye contact. Storing this material does not require special conditions. All it needs is a good air ventilation in the storage space.

In case of inhalation, the affected person must be taken out, to fresh air, and kept in a comfortable position so he/she can breathe properly. If he/she has difficulties breathing, oxygen can be administered. If he/she stops breathing, CPR manoeuvres can be performed. In this case, a medical intervention is also necessary.

Avoid direct contact with the skin. If your skin entered in direct contact with this abrasive material, you must wash the affected area with clean water for 20 minutes. Use a soft soap and clean water.

In case of ingestion, a doctor’s intervention is necessary. All treatments applied to the victim must take into account the symptoms showed by that victim.

Avoid walking through the material and always wear personal protective equipment. In case of leakages, one must insulate the area on an approximately 25 meters radius in all directions. It is forbidden to spill this material in water. Please avoid dust. Use professional vacuum cleaners to clean the area.

This material comprises silicate crystals and/or quartz. According to the IARC Monographs for assessing the hazards posed by chemical substances to people, this material bears a potential risk of cancer.

for Water Jet Cutting

Testimonials

A beautiful collaboration, quality, promptitude and honesty carried us on a beautiful road...

Răzvan Harabagiu, Shareholder | Executive Manager, Alpaccess, Romania

A trustworthy brand, a professional team, a flawless service! We are happy to have them as our supplier for blasting agents and equipment.

Iulian Duna, Project Manager, Industrial Cruman, Ploiești - Romania

GritSablare, a reliable and fast partner, always involved to learn and find solutions that fits customers' needs.

Daniel Morari, COSMA Glass - water jet cutting

GritSablare, the largest blasting warehouse we are aware of... a flexible payment schedule for blasting equipment, moreover, a very good choice!

Ionel Zelca, Owner, Industrial Painting SRL - blasting and electrostatic painting

We provide first-class quality products, build long term relationships and develop strong connections with our clients