Natural mineral

Blasting Materials distributed by GritSablare are characterized by outstanding quality. This quality is reflected in an above-average service life, a very high productivity and value retention.

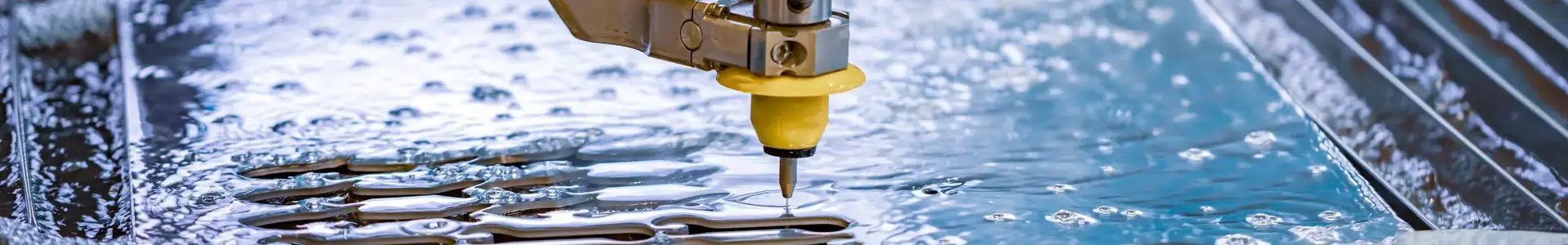

Olivine for Water-Jet Cutting

- OLIVINE is produced from olivine, a naturally occurring refractory mineral, composed of forsterite, Mg2SiO4 and fayalite Fe2SiO4.

- Features: The high refractory value of 1760°C is achieved through its effective oxide content of approximately 49% Magnesium oxide, 42% Silicon dioxide and 7% Iron oxide. OLIVINE finds application over the entire range of fired and chemically bonded basic refractory applications.

- With high chemical stability and high impact resistance, olivine is an ideal material for multiple water jet cutting applications, where a high level of accuracy is a priority.

ISO Certified 14001

ISO Certified 50001

Water Jet Cutting

- Olivine No 11 PO (< 0.063 mm)

- Olivine AFS 120 DS (0.063 - 0.125 mm)

- Olivine MIX 1675 DS (0.063 - 0.180 mm)

- Olivine AFS 80 DS (0.090 - 0.180 mm)

- Olivine AFS 50 DS (0.180 - 0.250 mm)

- Olivine AFS 45 DS (0.180 - 0.500 mm)

- Olivine AFS 30 DS (0.355 - 0.710 mm)

- Olivine MIX 1800 DS (0.125 - 0.710 mm)

- Olivine AFS 20DS (0.710 - 1.40 mm)

- Bulk Bags

- Big Bags

- Bags of 25 Kg (Moisture Proof Paper Bags)

- The material must be stored in a dry place.

Olivine Description

- Additions of OLIVINE refractory grade fillers and aggregates can resist chemical attack, increase impact strength and thermal stability, and improve insulating properties. Highly resistant to neutral and basic slags, and non-reactive with most molten metals, OLIVINE is an excellent refractory aggregate in primary metals production.

- OLIVINE’s thermal conductivity is lower than comparable basic refractory raw materials such as dead burned magnesite and dolomite. This property makes it ideal for insulation linings in continuous steel casting and for steel ladles. A low and uniform thermal expansion over the entire temperature range creates stability in all refractory uses.

- All OLIVINE refractory fillers and aggregates are produced with adherence to ISO 9001, ISO 14001 and ISO 50001; quality, environmental and energy management systems.

Physical and Chemical Properties

| Parameter | Method | Unit | Typical Value | |

|---|---|---|---|---|

| Specific Gravity | g/cm3 | 3.25 | ||

| Initial Sintering | °C | Aprox. 1450 | ||

| Melting Point | °C | Aprox. 1760 | ||

| Thermal Expansion | at 1200°C - Linear | % | Aprox. 1.1 | |

| Bulk Density, Loose | EN 1097-3 | g/cm3 | 1.7 | |

| Hardness | Mohs's Scale | 6.5 – 7.0 | ||

| pH (milled) | 8.9 – 9.5 |

| Olivine No 11 PO | Olivine AFS 120 DS | Olivine MIX 1675 DS | Olivine AFS 80 DS | Olivine AFS 50 DS | Olivine AFS 45 DS | Olivine AFS 30 DS | Olivine MIX 1800 DS | Olivine AFS 20DS | ||

|---|---|---|---|---|---|---|---|---|---|---|

| MgO | Magnesium Oxide | 46.5 | 49.3 | 49.4 | 49.7 | 50 | 50 | 50.2 | 49.9 | 49.9 |

| SiO2* | Silicon Oxide* | 41.5 | 41.6 | 41.7 | 41.8 | 41.6 | 41.5 | 41.4 | 41.5 | 41.5 |

| Fe2O3 | Iron Oxide | 6.8 | 7.6 | 7.4 | 7.5 | 7.4 | 7.4 | 7.4 | 7.4 | 7.4 |

| Al2O3 | Aluminium Oxide | 0.75 | 0.3 | 0.42 | 0.3 | 0.41 | 0.42 | 0.42 | 0.4 | 0.34 |

| Cr2O3 | Chromium Oxide | 0.44 | 0.77 | 0.55 | 0.44 | 0.29 | 0.28 | 0.26 | 0.36 | 0.32 |

| NiO | Nickel Oxide | 0.3 | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 | 0.32 |

| MnO | Mangan Oxide | 0.08 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 |

| L.O.I.** | Loss on Ignition** | 4 | 0.6 | 0.7 | 0.6 | 0.6 | 0.6 | 0.6 | 0.7 | 0.7 |

* Present as silicate, contains ≶ 0.1% free crystalline silica.

** Weight reduction after 30 minutes at 900°C/air.

Olivine User Safety

Olivine is a safe, ecologic and stable material. It does not need special attention while handled. Wearing personal protection equipment is necessary, as well as avoiding eye contact. Storing this material does not require special conditions. All it needs is a good air ventilation in the storage space.

In case of inhalation, the affected person must be taken out, to fresh air, and kept in a comfortable position so he/she can breathe properly. If he/she has difficulties breathing, oxygen can be administered. If he/she stops breathing, CPR manoeuvres can be performed. In this case, a medical intervention is also necessary.

Avoid direct contact with the skin. If your skin entered in direct contact with this abrasive material, you must wash the affected area with clean water for 20 minutes. Use a soft soap and clean water.

In case of ingestion, a doctor’s intervention is necessary. All treatments applied to the victim must take into account the symptoms showed by that victim.

Avoid walking through the material and always wear personal protective equipment. In case of leakages, one must insulate the area on an approximately 25 meters radius in all directions. It is forbidden to spill this material in water. Please avoid dust. Use professional vacuum cleaners to clean the area.

your water-jet cutting applications?

Testimonials

A beautiful collaboration, quality, promptitude and honesty carried us on a beautiful road...

Răzvan Harabagiu, Shareholder | Executive Manager, Alpaccess, Romania

A trustworthy brand, a professional team, a flawless service! We are happy to have them as our supplier for blasting agents and equipment.

Iulian Duna, Project Manager, Industrial Cruman, Ploiești - Romania

GritSablare, a reliable and fast partner, always involved to learn and find solutions that fits customers' needs.

Daniel Morari, COSMA Glass - water jet cutting

GritSablare, the largest blasting warehouse we are aware of... a flexible payment schedule for blasting equipment, moreover, a very good choice!

Ionel Zelca, Owner, Industrial Painting SRL - blasting and electrostatic painting

We provide first-class quality products, build long term relationships and develop strong connections with our clients