Blasting Workshop with Commercial Store for Blasting Equipment

Blast with...

Test...

Buy...

In our blasting workshop:

- You learn everything about blasting and surface preparation, and further, all you need to know regarding establishing a new business in the blasting sector

- You can blast the work pieces you need at the moment, using our professional blasting equipment

- You can test our blasting equipment

- You can buy professional blasting equipment from us and we provide you all the technical assistance necessary for installment and use

The most modern blasting equipment

We offer you the most comprehensive offer:

(1) Professional blasting equipment for any type of blasting application, regarding of the type of surface or dimension;

(2) Efficient and non-toxic blasting materials, compatible with any type of blasting equipment.

Blasting Equipment for advanced application

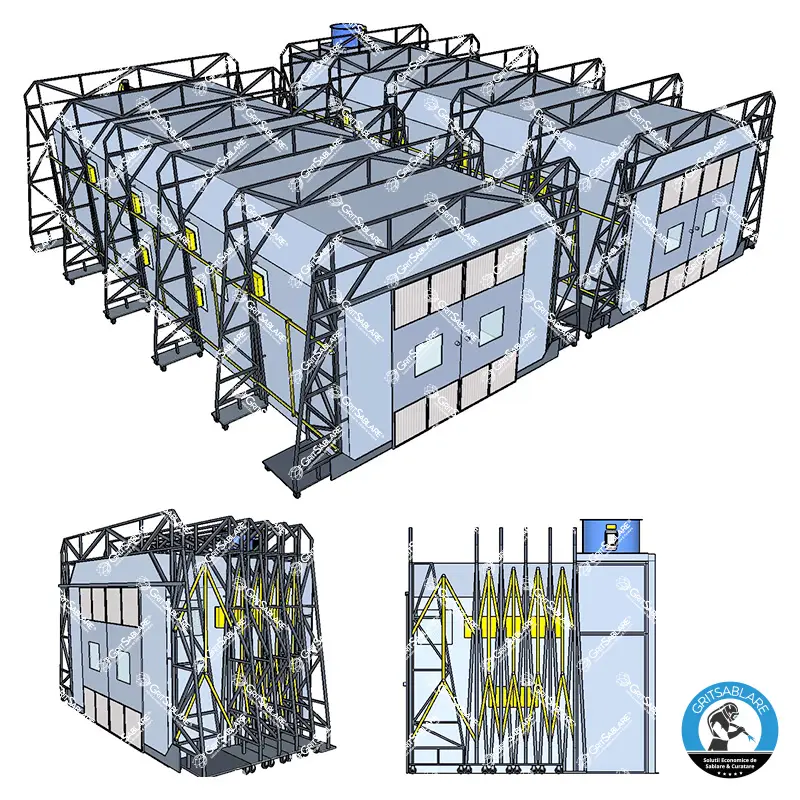

Blasting Room and Paint Room, Retractable System Cortina by GritSablare

Advantages:

- Cortina / retractable system – saving on factory floor space when blasting or coating procedures are not required.

- Portability – Able to easily relocate and position to meet with all project requirements.

- Fabric Enclosure Material – Fire Resistant

- Internal Walls – Rubber Lining for extended service life

- Main Entry Doors – Full access sliding type

- Room Lighting – LED

- Blast Room Ventilation System – In compliance with International Standards

- Paint Room Extraction System – In compliance with International Standards

Compatible abrasives:

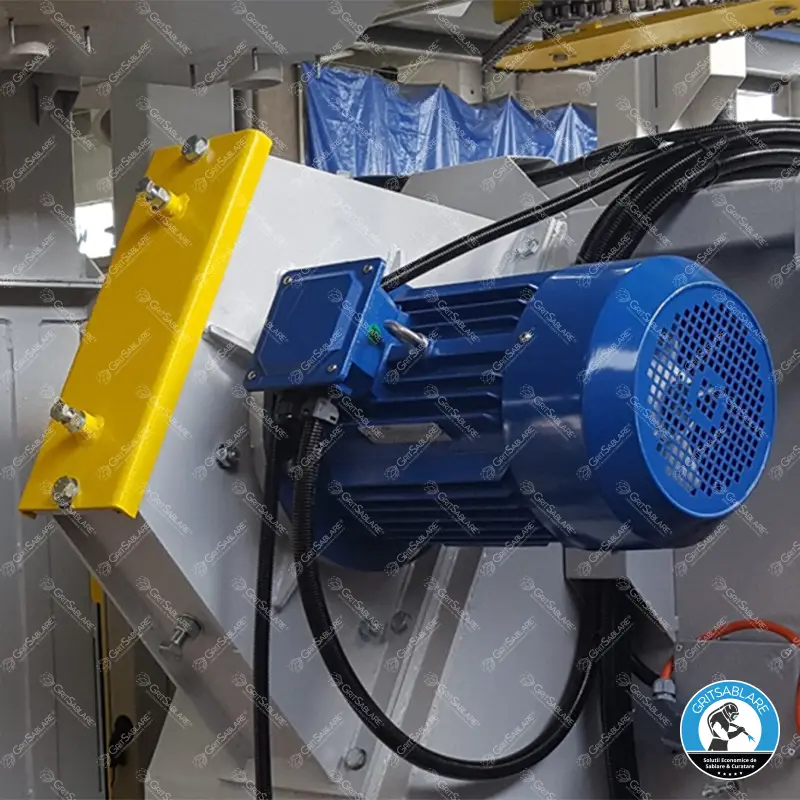

Blast Wheel Turbine BVM 366 by GritSablare

Advantages:

- High efficiency monowheel BV’s turbines mod. BVM 366 are suitable for all shotblasting plants to increase the yield of the treatment.

- Runner head diameter is 360 mm and is obtained by a singular disk where the components are assembled in easy way.

- The main feature is a large number six (6) big blades fixed to the disk by means of a quick joint.

- The shot spread speed is calculated in 82 m/min with RPM 3.000 route/minute.

- Steel made turbine body finished on CNC machines with all internal wear protection plates made of NI-HARD alloy of easy replacement to warranty a longer protection and duration of the components.

- Central feeding system with bushing to control the blasting spread direction with easy adjustable device.

- Direct-coupling electric motors with the runner head and settable by electronic inverter to regulate shot speed and shot flow.

Compatible abrasives:

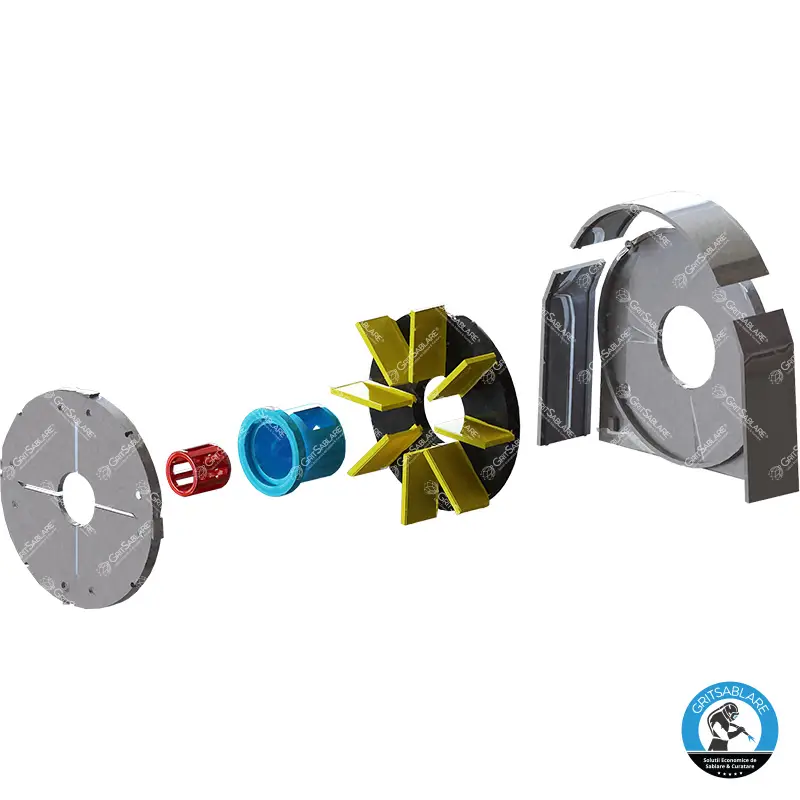

Blast Wheel Turbine SPEEDLOCK by GritSablare

Advantages:

- The bi-direction wheel is available in either 13” (330 mm) diameter configuration, or can be supplied with extended vanes, which increase the effective wheel throwing diameter to 15” (380 mm).

- When compared to double cheek blast wheels, the Speedlock wheel offers significant weight savings, and this can be used as a selling feature, because the reduced mass will absorb less power. The power saved can then be used to throw more abrasive at the product, thus increasing the efficiency of the system.

- The blast wheel is fitted to the motor shaft by way of a reverse taper lock arrangement, with the screws protected by the impeller during operation. Such a simple design makes the removal of the wheel reasonably straight forward.

Compatible abrasives:

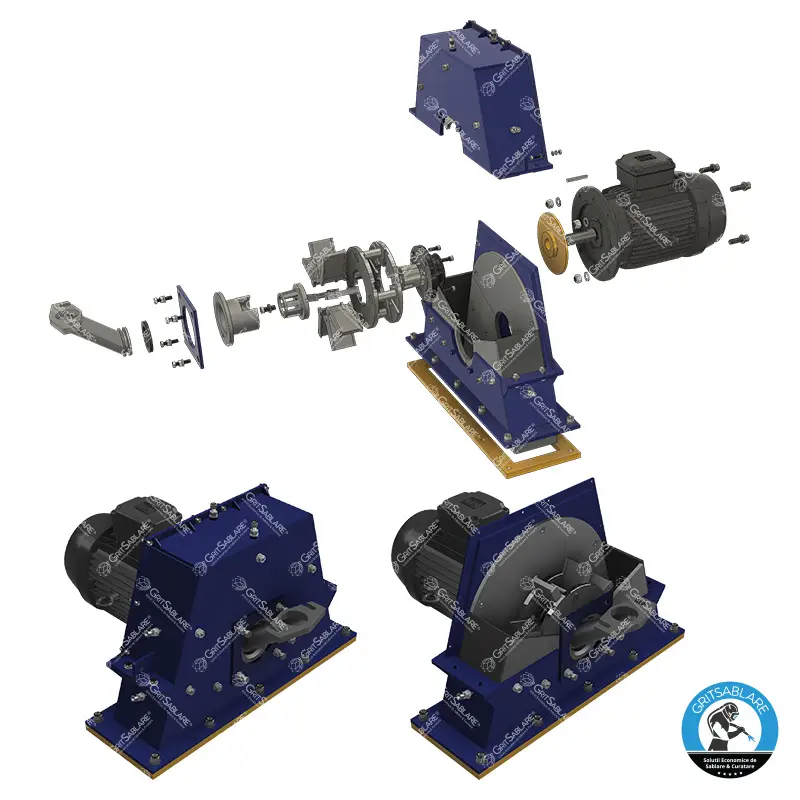

Blast Wheel R370F by GritSablare

Advantages:

GritSablare direct drive blast wheels are high efficiency direct drive units mounted on a heavy duty 20mm thick base plate with a cast iron frame TEFC flange mounted motor. The maintenance design allows for many parts to be replaced without the need to remove the wheel hood. The cast wheel parts are hardened to HRC 60+ and all rotating parts are dynamically balanced. The blast wheel motor is protected from the abrasive by a Triple Seal System.

- Available in a multitude of sizes and configurations to meet with all shot blasting machine requirements.

- Wheel Blades (Cast): Shell Molded 18-20% Chrome Iron Alloy with 1.5% Moly, hardened to HRC 60+

- Wheel Blades (Machined): Alloy, precision machined and hardened to HRC 60+

- Hood Liners: Cast 18-20% Chrome Iron Alloy hardened to HRC 60+

- Hood End Wear Plates: Cast 18-20% Chrome Iron Alloy hardened to HRC 60+

- Blast Wheel: Machined Alloy hardened to HRC 60+ and dynamically balanced

- Dispenser Housing and Dispenser: Shell Molded 18-20% Chrome Iron Alloy with 1.5% Moly hardened to HRC 60+

- Feed Chute: Chilled Cast Iron

Compatible abrasives:

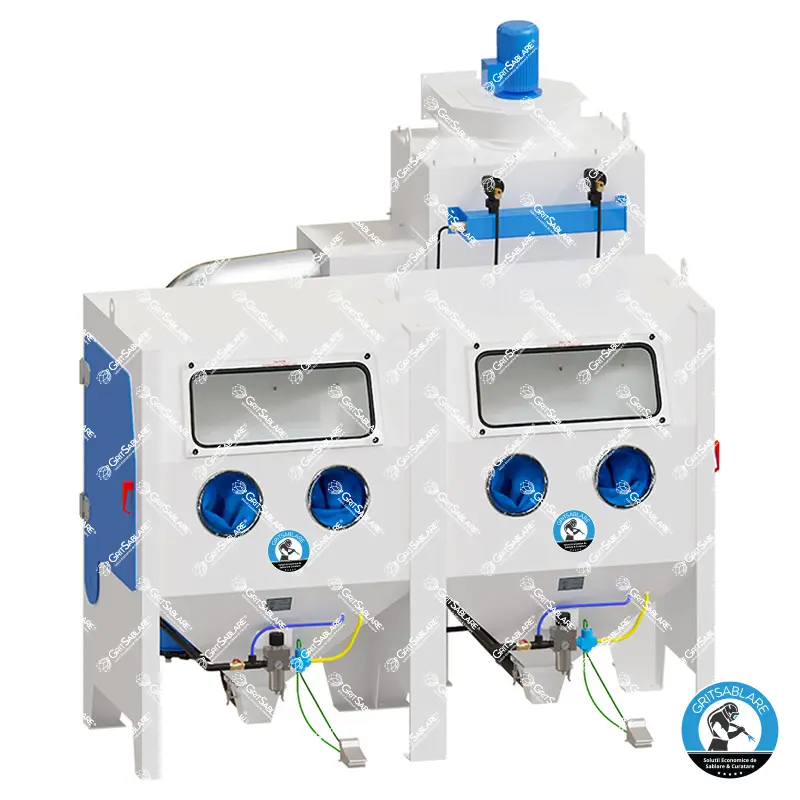

Blasting Cabinet GS2000HD (Heavy Duty) by GritSablare

Advantages:

The Blasting Cabinet GS2000HD by GritSablare highly efficient, extra large capacity industrial blast cabinet, compatible with a wide range of abrasive media, including: • Angular Steel Grit Premium & Steel Shots for Shot Peening Premium • Stainless Steel Grit & Stainless Steel Cut Wire Shots • Red Garnet • White Fused Aluminium Oxide Abrasive (WFA) & Brown Fused Aluminium Oxide Abrasive (BFA) • Glass Beads • Nickel Slag - Angular Blasting Grit • Copper Slag

- Cyclone type abrasive separator cleans the abrasive during use.

- Safety door interlock.

- Integral dry cartridge reverse pulse dust collector for clear visibility.

- Heavy duty, wear resistant rubber gloves.

- Quick-change laminated glass viewing window - no tools required.

- Fully adjustable abrasive feed tee.

- Compressed air regulator and gauge.

- High performance Delta Suction Gun.

- Standard air blow down gun.

Compatible abrasives:

Professional Blasting Cabinets for Blasting Workshops

Professional Blasting Installations for Workshops

Testimonials

A beautiful collaboration, quality, promptitude and honesty carried us on a beautiful road...

Răzvan Harabagiu, Shareholder | Executive Manager, Alpaccess, Romania

A trustworthy brand, a professional team, a flawless service! We are happy to have them as our supplier for blasting agents and equipment.

Iulian Duna, Project Manager, Industrial Cruman, Ploiești - Romania

GritSablare, a reliable and fast partner, always involved to learn and find solutions that fits customers' needs.

Daniel Morari, COSMA Glass - water jet cutting

GritSablare, the largest blasting warehouse we are aware of... a flexible payment schedule for blasting equipment, moreover, a very good choice!

Ionel Zelca, Owner, Industrial Painting SRL - blasting and electrostatic painting

We provide first-class quality products, build long term relationships and develop strong connections with our clients